District News

One-Hundred and Eleven Miles

by Clifford Swoape

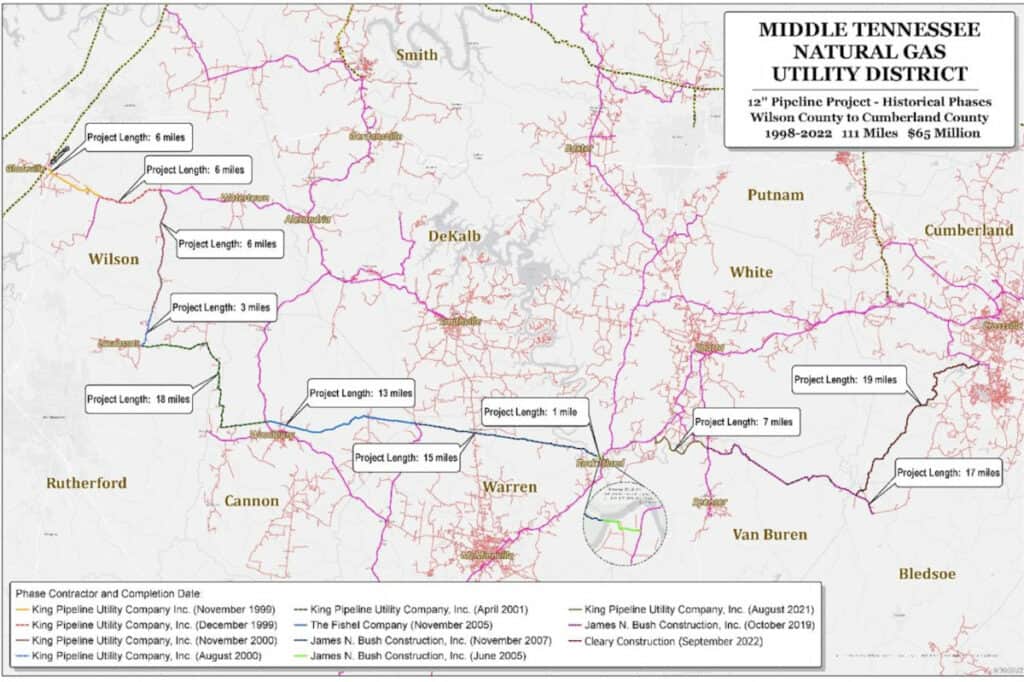

On September 19, 2022, Middle Tennessee Natural Gas Utility District (MTNG) reached 100% natural gas on a new section of pipe. “No big deal,” you might say; “MTNG does that almost daily.” However, this 12” steel pipe section completed by Cleary Construction in Cumberland County was such a significant accomplishment for MTNG that an official “valve-turning” ceremony was held on October 18, complete with Commissioners, Contractors, MTNG Employees, and Retirees. The celebration was for finishing a pipeline project over twenty-four years in the making. The Project had several phases but has all been referred to simply as the 12” Project.

Way back in the twentieth century, MTNG began the planning phases and approvals for the installation of what was then (and still is) our single largest pipeline in the District. Work began by installing pipe underneath what would become Interstate 840 and a bustling industrial area. At the time, it was a piece of pipe buried deep in the middle of “nowhere,” initially not even connected to anything. The counties served by MTNG were growing so fast that our leadership recognized that the demand for natural gas would soon outpace our capacity to deliver it to customers. So, in November 1999, Phase 1 was completed by King Pipeline Utility Company, Inc., with the installation of six miles of 12” steel pipe in Wilson County at an average cost of $214,000 per mile.

The 12” Project required eleven phases, over twenty-four years of effort including the work of four different pipeline contractor companies and their subcontractors, incalculable hours by MTNG personnel, massive materials acquisition, the issue of bonds, tenacity, vision, bureaucratic wrangling, environmental protection, and a total price tag of $65 million. The pipeline’s 111-mile journey crossed Wilson, Rutherford, Cannon, Warren, White, Van Buren, Bledsoe, and Cumberland Counties, eight counties total. It was overseen by three different CEOs and bore witness to the changing of every MTNG Department Head at least once during the construction. We lost count of how many MTNG personnel inspected the construction. Easements were obtained. The right of way was cleared. Fences and roads were cut and repaired. Some roads actually had to be constructed to get equipment to the pipeline locations. We did this while building a pipeline in compliance with all requirements and permits for pipeline safety, worksite safety, construction specifications, safe digging, water crossings, environmental protection, and being a good neighbor. We learned new words like “dual flow stations” and “zinc ribbon anodes.” We learned about and protected endangered East Fork Stones River Crayfish and Indiana Bats. We saw how difficult it was to “bend” a piece of 12” steel, and we know precisely how rocky it is from Gladeville to Crossville by way of Woodbury and Rock Island.

I was at the initial public and pre-construction meetings when the 12” Project began. Then Chief Draftsman Earl Parker had to piece together a giant map from a couple of Tennessee Gazetteers (think 11×17 topographical road atlas) because we did not have a printer large enough back then. We all stood over the giant map still tucked away in our Training Center and said things like “Where is Norene?” and “This is going to be a BIG project!” and “Have you actually seen how steep those hills are?”

Many who work at MTNG now were not even born when this Project started. Some may wonder at the value of spending $65 million to run one pipeline. I was ten years into my career when this began. So, I can tell you,this is not only a monumental accomplishment but was necessary and visionary. It is money incredibly well-spent. This pipeline provides natural gas capacity that will enable industries and businesses to bring jobs and prosperity to our counties. It provides families with the year-round comfort of natural gas heating, cooking, grilling, laundry, and hot water. Furthermore, the interconnections and natural gas storage space provided by this 12” line protect our system from emergencies that would shut down other utilities.

So, I tip my hat to the visionaries who anticipated the need and did the work necessary to meet it. I give a nod to King Pipeline, the Fishel Company, James N. Bush Construction, and Cleary Construction for their work from start to finish. I send a big THANK YOU to every MTNG commissioner, employee, contractor, business partner, customer, and anyone else who helped make this magnificent milestone possible. It is humbling to have witnessed this 12” Project from start to finish. It took a fantastic amount of teamwork and effort. It is EXACTLY what our District was created to do in 1955. MTNG supports the growth of the communities we serve by providing safe, reliable, and competitive natural gas service. This project will make our communities stronger and help keep our natural gas supply safe, reliable, and affordable. We are your hometown energy partner, and you can reach us at 1-833-GET-MTNG (438-6864) or online at MTNG.com.

Safety & Reliability

Middle Tennessee Natural Gas Utility District (MTNG) works year-round to ensure natural gas is delivered safely and reliably to the homes and businesses in our communities. We meet or exceed all federal and state safety standards. MTNG never stops at the minimum; we continuously go above and beyond. We sell natural gas, but we deliver safety and reliability. Our highly trained and skilled workforce makes this possible by:

- Odor Complaint / Carbon Monoxide / Leak Investigation – It is such a core component of what we do that we often forget to talk about it. MTNG technicians are available every hour of every day of the year to respond to any report of a possible gas leak or carbon monoxide issue.

- Line Patrol – MTNG patrols our high-pressure lines annually to ensure there are no potential safety issues. We are on the lookout for washouts, potential landslide areas, exposed pipes, cathodic shorts, overgrown vegetation around our facilities or construction near them, and many other potential causes of leaks or threats to the continued safe operation of our system.

- Public Building Safety Survey – In areas where people gather in large numbers, and particularly where those areas are surrounded by pavement that can cause a natural gas leak to migrate, MTNG checks the natural gas mains, service lines, and even customer fuel lines for possible leaks annually. We keep a running list of structures that meet the criteria for the extra safety measure.

- Safety Survey – At regular intervals, MTNG physically inspects every mile of our pipe in and above the ground with incredibly sensitive methane detectors to find leaks before they are even large enough to be detected by human senses. Federal law requires natural gas operators to perform this safety survey a minimum of every five years. MTNG surveys parts of our system each year so that we inspect all of our lines every three years. This proactive step helps keep everyone safe, our system operating smoothly, and it is good for the environment.

- Annual Maintenance – MTNG does a host of regular annual maintenance on our system to keep it running smoothly. This includes inspection and maintenance of regulators, valves, reliefs, stations, meters, corrosion prevention efforts, odorization equipment, telemetry, and pipe crossings.

- Damage Prevention & Public Awareness– The single biggest threat to our system is third-party damage. So, we also work year-round to educate the public, and excavators in particular, about natural gas lines in the area, how to dig safely around them, and what to do in the event of a natural gas leak. These efforts include annual mailings to excavators in our area, the installation of line markers near our lines, active participation in the Tennessee One-Call System, ads of all kinds reminding everyone to call 811 before digging, public liaison meetings with emergency responders, and sponsoring PIPE Meetings for stakeholder groups in twenty-three Tennessee counties.

At MTNG, we work faithfully year-round so you can relax and enjoy the comfort natural gas provides. We appreciate you providing access to our pipelines and facilities so that we can fulfill our mission.

MTNG Brings Natural Gas Service to Captain’s Point Community in DeKalb County

By Sam Morrison

Middle Tennessee Natural Gas Utility District (MTNG) is pleased to announce the completion of a new main to serve Highway 56 and the Captain’s Point community along Center Hill Lake. MTNG had two different contractors working on the Captain’s Point line; installing new main in tough Tennessee rock. Johnson Construction extended a 4” PE main along TN Highway 56 to get to the subdivision . Then, Bush Construction installed a 2” PE main inside Captain’s Point.

Homes in this community will be able to benefit immediately from comfortable and affordable natural gas. The additional 4” main down TN Highway 56 also gives MTNG the ability to serve future expansion in this area along Center Hill Lake. This is just one more way that MTNG supports the growth of the communities we serve. This is what Utility Districts were created to do!

Nokian Tyres

Thanks in part to the ready availability of affordable, reliable natural gas, Nokian Tyres (not a typo that is the correct spelling) announced the grand opening of their North American production factory in Dayton, Tennessee. It is Nokian’s third global production facility and is one of the most advanced in the world. The Dayton factory will strengthen Nokian’s presence in the North American market by providing tailored products and superior service to their customers. It also carries significant local impact to the community: as many as 400 jobs once the factory reaches full capacity of up to four million tires per year.

Nokian Tyres roots go all the way back to 1898, when Suomen Gummitehdas Oy, or Finnish Rubber Factory, was established. The plant was announced in May of 2017. Since then, Middle Tennessee Natural Gas Utility District Engineering and Operations personnel have worked with contractor Bush Construction to install a 6” high-pressure steel line to the building, a 4” high-pressure stub-out for future use, a regulator station, and an industrial meter set. Dayton Superintendent Eddie Morgan said, “We are very thankful to have this industrial addition to Rhea County; it will bring great jobs and revenue to the county and even to the surrounding area.” This is just one example of the positive impact that our Utility District has in the communities we serve.

Thanks for choosing America’s Energy and welcome to Tennessee!

Information and images courtesy of Nokian Tyres www.nokiantires.com/daytonfactory.